Ingiant customized industrial bus slip ring transmission RS422 signal

|

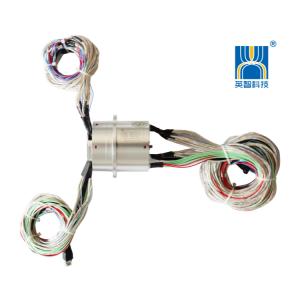

DHS052-24-1 |

|||

|

The main parameters |

|||

|

Number of circuits |

24 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

can be customized |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

Product drawing:

What is an industrial bus slip ring?

The industrial bus mainly solves the digital communication between intelligent instruments, controllers, actuators and other equipment in industrial sites, as well as the information transmission between these on-site control equipment and control systems. The design of the bus will directly affect the performance, reliability, scalability and upgradeability of the entire microcomputer system. According to the working principle of conductive slip rings, theoretically all industrial data bus rotation transmission problems can be solved by electric slip rings.

Industrial bus slip ring

Industrial data bus conductive slip ring customization

Industrial bus slip rings are specially designed for various industrial bus data transmission. Supports different bus types, such as CANBUS, Profibus, EtherNET, DeviceNET, RS422, RS485, RS232, PLC, DP, CC-LINK, etc.

Features

- Can transmit current, sensor, control circuit, Ethernet and other signals

- Stable performance, large return loss, small insertion loss, anti-crosstalk

- Unique coating process, long service life

- Optional RJ45 network interface

- Compatible with data communication protocols

Our advantage:

- Product advantage: The various Ingiant slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value.

- Company advantage: Owns complete mechanical processing equipments including a CNC processing center, with strict inspection and testing standards which can meet national military GJB standard and quality management system, moreover, Ingiant owns 27 kinds of technical patents of slip rings and rotary joints(include 26 untility model patents, 1 invention patent), so we have a big strength on R&D and production process. More than 60 workers with several years experience in workshop production, skilled in operation and production, can better guarantee product quality.

- customised advantage: The different Ingiant slip ring series are optimised for a wide range of applications. We support our customers for tailor-made solutions. All products can be individually adapted to the applications in order to offer you added value.