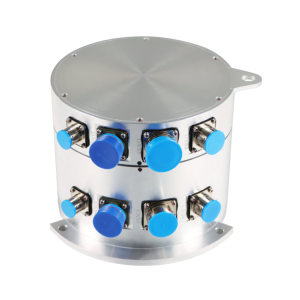

Ingiant Industrial bus slip ring outer diameter 32mm 64 channels electric signal used for Lithium battery equipment

|

DHS032-64 |

|||

|

The main parameters |

|||

|

Number of circuits |

64 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

can be customized |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

Standard product outline drawing:

Industrial bus slip ring: solid shaft slip ring

DHS032-64 industrial bus slip ring, ProfiNET slip ring, DeviceNet conductive slip ring, standard series integral precision industrial bus slip ring with outer diameter of 32mm. Supported bus types include: Profibus, CanBUS, CANOPEN, DeviceNET, CC-LINK, ProfiNET, EtherCAT, etc.

Typical applications:

- High-speed industrial bus with conductive slip ring, no packet loss

- Super strong anti-interference ability, never alarm

- Special internal shielding treatment

- Guarantee 100% communication without dead spots.

- Mainly designed for high-speed data and error-free transmission protocol

- The contact part adopts rare metal + hard gold plating treatment process to ensure wear resistance and oxidation resistance, thus ensuring an ultra-long service life.

Typical applications: bus communication between various encoders, servo motors and various controllers in industrial automation control, such as lithium battery equipment, various high-end intelligent equipment, various laser equipment, etc.

Our advantage:

- Product advantage: High rotating accuracy, more stable performance and longer service life. The lifting material is precious metal + superhard gold plating, with small torque, stable operation and excellent transmission performance. 10 million revolutions of quality assurance, so that you have no worries to cooperate with us.

- Company advantage: Owns complete mechanical processing equipments including a CNC processing center, with strict inspection and testing standards which can meet national military GJB standard and quality management system, moreover, Ingiant owns 27 kinds of technical patents of slip rings and rotary joints(include 26 untility model patents, 1 invention patent), so we have a big strength on R&D and production process. More than 60 workers with several years experience in workshop production, skilled in operation and production, can better guarantee product quality.

- Customized service, accurate response and technical support for customers, 12 months of the products warranty, no worry for after sales problems. With reliable products, strict qualitycontrol system, perfect pre-sale and after-sales service, Ingiant obtain strusts from more and more customers all over the world.