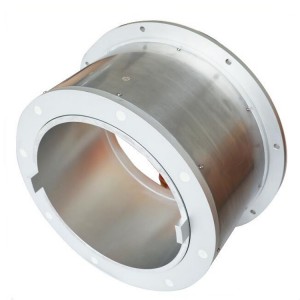

Ingiant Low Temp Application Through Bore Slip Ring 25channels hole diameter 260mm

|

DHK0260-25 |

|||

|

The main parameters |

|||

|

Number of circuits |

25 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

2A.5A.10A.15A.20A |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

|

Electrical Slip Ring Parameters |

|||

|

Rings |

1-200 (or more) |

Current |

2A,5A,10A,20A,25A |

|

Rated Voltage |

0~600VDC/VAC |

Max speed |

15000RPM |

|

Housing Material |

Aluminum Alloy, engineering plastic, stainless steel, etc |

Torque |

0.02N.m;+0.01N.m/ 6rings |

|

Working life |

>80 million |

Contact Material |

Precious Material |

|

Electrical Noise |

<5mΩ |

Contact resistance: |

<5mΩ |

|

Dielectric Strength |

2500VAC@50Hz |

Lead Wire |

UL Teflon@Awg22,Awg16 |

|

Insulation Resistance |

1000 MΩ / 500VDC |

Lead Length |

300mm (per required) |

|

Working Temperature |

-40℃~ 80℃ |

Protection Grade |

IP51 – IP68 |

|

Operating Humidity |

10% to 95% RH |

Material |

RoHs |

Standard product outline drawing:

Low Temp Application Through Bore Slip Ring

Through Bore Slip Rings are typically used in harsh environments such as high altitudes, which involve extreme cold temperatures.Ingiant has many designs suitable for high altitudes without performance loss.

What is a Low Temp Application Through Bore Slip Ring?

Through Bore Slip Rings can be drum or pancake-style and are designed specifically according to customer requirements. The through bore is driven by the customer’s needs but the slip ring itself still operates like any other slip ring without a bore. In some applications, the bore can be used to integrate a fiber optic rotary joint (FORJ). This integration can be done by Ingiant or by the customer, in which case Ingiant provides the interface features.

Our Advantage

- Product advantage: High rotating accuracy, more stable performance and longer service life. The lifting material is precious metal + superhard gold plating, with small torque, stable operation and excellent transmission performance. 10 million revolutions of quality assurance. Comprehensive quality management system, strict management in all aspects of design, manufacturing, testing, etc., to ensure the use of materials, coupled with high-precision imported equipment and high-tech technology to ensure, our products Performance and indicators are always at the forefront of similar products in the world.

- Company advantage: More than 10 years experienced senior engineers in the industry and 12 people R&D team, provide more professional and reliable solutions for your rotating conduction problems. More than 60 workers with several years experience in workshop production, skilled in operation and production, can better guarantee product quality. Depending on strong R&D ability and close cooperation with well-know enterprises & research institutes, Ingiant could not only provide standard industrial slip rings, but also customize different slip rings according to customer’s different requirements.

- Excellent after-sales and technical support service, by providing high-quality products and technical services, Ingiant has become the long-term designated qualified supplier for numerous military units &research institutes, domestic and foreign companies.