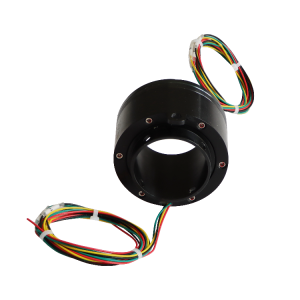

Ingiant non-standard customized through hole slip ring hole diameter 34mm 16 channels for textile machinery

|

DHK034-16-002 |

|||

|

The main parameters |

|||

|

Number of circuits |

16 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

2A.5A.10A.15A.20A |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

Standard product outline drawing:

Through hole slip ring – DHK034 non-standard customized series

Customization is supported, standardized product inner diameter: 3-500mm, current :2-1000A

DHK034-16-002 through hole slip ring, aperture 34mm, suitable for rotating electromechanical systems with a diameter less than 34mm, standard power ring 10A/ring, maximum 24 rings, signal ring 5A/ring, maximum 48 rings, used for 360-degree power or signal transmission. Can be used in cranes, packaging machines, winding bobbins, filling machines, textile machinery, automatic winding machines, small and medium-sized amusement equipment, etc.

Product features

- Power, signal and data can be integrated into a rotating transmission system without interference

- Temperature control signal and thermocouple signal can be transmitted at the same time

- Fiber brush bundle process ensures reliable contact and low friction coefficient

- Adopts more reliable all-metal shell protection structure

- Integrated design, easy to install

- 3-500mm aperture optional

- 0-20A current, 0~600VAC/VDC voltage optional

- 1-300 channels optional

Typical applications: Packaging machinery, automated machine tools, coating machines, automatic screw locking machines, carpet gunning robots, intelligent grinding robots, polishing machines, intelligent storage robots, cable reels, die presses, centrifuges, storage logistics vehicles, spraying equipment, and any other device that requires 360° rotation to conduct electricity or transmit various control signals.

Our Advantage

- Product advantage: High rotating accuracy, more stable performance and longer service life. The lifting material is precious metal + superhard gold plating, with small torque, stable operation and excellent transmission performance. 10 million revolutions of quality assurance, so that you have no worries to cooperate with us.

- Company advantage: Ingiant provide both OEM and ODM services for world famous brands and customers,our factary covers an area of more than 6000 square meters of scientific research & production space and with a professional design & manufacturing team of more than 100 staffs, our strong R&D strength make us be able to meet customers’ different requirment.

- Excellent after-sales and technical support service:Customized, accurate and timely service for customers in terms of pre-sales, production, after-sales and product warrenty, our goods are guaranteed for 12 months from date of sale,under guaranteed time non human damage, free maintenance or replacement for quality problems arising from the products.

2022.5.5-1_副本.png)

2022.5.5-1_副本-300x300.png)

2022.5.5-2_副本-300x300.png)

2022.5.5-3_副本-300x300.png)