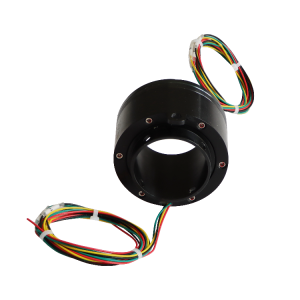

Ingiant Pancake slip ring inner diameter 113mm 14 channels power used for Rotary tables

|

DHK113-14-002 |

|||

|

The main parameters |

|||

| Number of circuits | 14 | Working temperature | “-40℃~+65℃” |

| Rated current | 2A.5A.10A.15A.20A | Working humidity | <70% |

| Rated voltage | 0~240 VAC/VDC | Protection level | IP54 |

| Insulation resistance | ≥1000MΩ @500VDC | Housing material | Aluminum Alloy |

| Insulation strength | 1500 VAC@50Hz,60s,2mA | Electrical contact material | Precious metal |

| Dynamic resistance variation | <10MΩ | Lead wire specification | Colored Teflon insulated & tinned stranded flexible wire |

| Rotating speed | 0~600rpm | Lead wire length | 500mm + 20mm |

Standard product outline drawing:

DHK113-14-002 Pancake slip ring has an inner diameter of 113 mm and uses state-of-the-art fiber brush technology and precious metal or gold contact design to ensure low electrical noise, high data transfer rate and low contact pressure.

Pancake slip ring is similar to through hole slip ring but is especially used for the rotating system with a height limit. Also called flat slip ring, flat disc electrical slip ring, or platter slip ring, since the shape is similar to a platter, rings, and brushes contact around the center of the circle. Pancake slip ring components include stator, rotor, and contacts, mainly used for transmitting precise signals and power or combined with pneumatic and hydraulic media. More electrical power, current, and signal circuits can extend broadwise limitless on flat diameter.

Pancake slip rings can be configured in two types, integrated and separated.

Integrated rings type can be designed for solid or through hole rotating systems.

The separated ring type is composed of a separated rotor and contact brush, which can be designed with PCB.

Feature

- High rotating speed

- Min. 6mm thinckness

- Can use superior fiber brushes, precious metal

- Can combine power and signals

- Fully customized solution

Pancake slip rings are predominantly engaged across many sectors due to their ability to fulfill diverse power and signal transmission requirements. They can be found in automotive, aerospace, marine, healthcare, communication, manufacturing, and many more industries.

Our Advantage

- Product advantage: With many years of R&D and manufacturing experience, Ingiant has quantitatively produced PCB slip rings with a minimum thickness of 6mm. The minimum thickness of ordinary spring-type slip rings can be 16mm. They have the advantages of low contact pressure, high data transmission, and low electrical noise. The inner and outer diameters and heights can be customized.

- Company advantage: 27 kinds of technical patents of slip rings and rotary joints(include 26 untility model patents, 1 invention patent. Provide OEM and ODM service, over 20 years of industry-related industry experience.

- Customised advantage: Leading Manufacturer of Standard, Customized Slip Ring & Rotary Unions for Many Industries.High Quality Components, Lower Costs, Over 800 Million Revolutions, 20+Years Working Life,Premium Expert Service,Reliable Quality,Competitive Price.