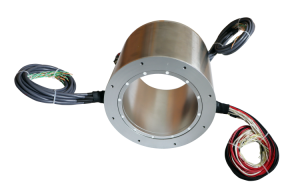

Ingiant through hole slip ring 3 channels 200A,2 channels 10A.

|

DHK074-5-002 |

|||

|

|

|||

|

Number of circuits |

5 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

2A.5A.10A.15A.20A |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

All of the above can be customized except (Insulation resistance. Insulation strength. Dynamic resistance variation), if there is no suitable standard products, can be customized according to your requirements

Standard product outline drawing:

The unobstructed bore through the center provides routing space for hydraulics, pneumatics or for a concentric shaft mount. Our through-bore slip rings use primarily fiber brush technology which offers several advantages over conventional slip ring technology, including multiple points of contact per brush bundle, low contact force per fiber and low contact wear rates. In addition, fiber brushes do not require lubrication and produce virtually no wear debris.

Capability

With over 10,000 designs, if you do not see a slip ring to match your requirements, please contact us for assistance. Our slip rings are aggressively priced, available for fast delivery and are designed for tough commercial, industrial, aerospace and military environments.

Our Advantage

- Product advantage: DHK series perforated conductive slip ring is currently the most cost-effective industrial slip ring inside a best-selling series of products, in many cases also known as hollow shaft conductive slip ring, through the hole, through the hole conductive slip ring, hollow shaft slip ring. Mainly used in 360 degrees continuous rotation and need to ensure that the power supply, signal can not be interrupted.

- Company advantage: As manufacturer of various slip ring bodies,Ingiant elies on a combination of targeted design processes, a selection of the best raw materials, professional production conditions, 100% quality control and professional assembly at the customer’s site.

- Excellent Customized advantage: We can supply you with quantities from 1. Special shapes or special types are possible on request. Give us a call. We will discuss your challenges until we have found your optimal slip ring. Trust our competence and experience. Our encapsulated miniature slip rings are used in tens of thousands of applications worldwide.