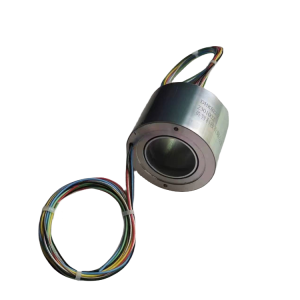

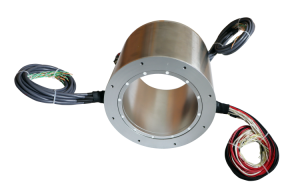

Ingiant through hole slip ring hole diameter 22mm 7channels

|

DHK022-7 |

|||

|

The main parameters |

|||

|

Number of circuits |

7 |

Working temperature |

“-40℃~+65℃” |

|

Rated current |

2A.5A.10A.15A.20A |

Working humidity |

<70% |

|

Rated voltage |

0~240 VAC/VDC |

Protection level |

IP54 |

|

Insulation resistance |

≥1000MΩ @500VDC |

Housing material |

Aluminum Alloy |

|

Insulation strength |

1500 VAC@50Hz,60s,2mA |

Electrical contact material |

Precious metal |

|

Dynamic resistance variation |

<10MΩ |

Lead wire specification |

Colored Teflon insulated & tinned stranded flexible wire |

|

Rotating speed |

0~600rpm |

Lead wire length |

500mm + 20mm |

All of the above can be customized except (Insulation resistance. Insulation strength. Dynamic resistance variation), if there is no suitable standard products, can be customized according to your requirements

Standard product outline drawing:

Through hole slip rings are a general term for a series of conductive slip rings with a hole in the center. They are mainly used to transmit precise signals, strong currents, large currents, and high voltages; they have low torque, low loss and no maintenance; low electrical noise, and are ultra-long Main features such as lifespan

Advantage

1. The current size is optional.

2. The shell is made of aluminum alloy shell.

3. Freely choose the high sealing grade and high-speed model of the slip ring.

4. There are various electrical access solutions and different electrical access combinations can be provided.

5. Strong environmental adaptability. In an environment with frequent vibrations, the through-hole slip ring can also work abnormally and has good anti-seismic performance. While transmitting large currents, it can also transmit multiple communication control signals at the same time without interference. In addition, through-hole slip rings also have the characteristics of high and low temperature resistance and corrosion resistance.

6. Well-designed pneumatic In other words, we can hydraulically rotate the shaft center hole.

7. Through hole diameters of various specifications can be freely selected.

8. Advanced multi-point contact technology ensures safe and reliable contact.

Through hole slip rings have been widely used in my country and are mainly used in magnetic actuators, turntable test sensors, manufacturing and control equipment, medical equipment, manufacturing and control equipment and other applications.

Our Advantage

1)Product advantage: Our products convince by high performance, wear resistance and high material quality of the contacts, which leads to high plant availability, flexibility and an economic price/performance ratio. A special focus is also placed on minimum friction and the lowest possible maintenance intensity.

2)Company advantage: As manufacturer of various slip ring bodies,Ingiant elies on a combination of targeted design processes, a selection of the best raw materials, professional production conditions, 100% quality control and professional assembly at the customer’s site.

3)Customised advantage: we offer modular slip ring systems that can be completely individually adapted to your needs. our slip ring bodies are convincing even under rough environmental conditions and temperatures.